Fire Resistance

15 Minute Thermal Barrier

The International Building Codes (IBC) and International Residential Code ( IRC) specify that SIPs shall only be used on buildings of combustible construction. (Type V)

The IBC and IRC building codes further state that any foam plastic insulation shall be separated from the interior of the building by an approved 15 minute thermal barrier consisting of ½” of gypsum wall board or an equivalent thermal barrier. Since the core of a SIP is a foam plastic, the inside of a wall or roof panel will need to be covered by a 15 minute thermal barrier.

The APA has reported that 23/32” western species plywood or OSB will meet the 15 minute thermal barrier. This report additionally states that, according to IBC section 2603.4.1.5, 15/32” plywood or OSB prescriptively meet this thermal barrier requirement for roof assemblies.

Beside gypsum wall board, plywood and OSB, other materials such as T&G decking may meet the 15 minute thermal barrier requirement. However, before proceeding, consult your local building code or inspector. While decisions made within one code jurisdiction may be considered as a precedent for others, the final decision on materials not specifically listed in the code, are usually made on a case-by case basis within each jurisdiction.

Fire Resistance Ratings

|

Online Certifications Directory |

| BXUV.U532 Fire Resistance Ratings – ANSI/UL 263 |

|

| Design / System / Construction / Assembly Usage Disclaimer | |

|

|

| Fire Resistance Ratings – ANSI/UL 263 See General Information for Fire Resistance Ratings – ANSI/UL 263 Design No. U532 August 08, 2001 Bearing Wall Rating – 1 Hr |

|

|

|

|

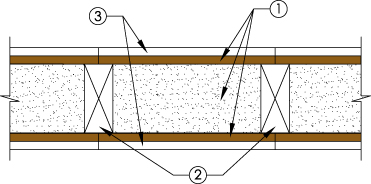

1. Building Units* – Composite panels of a nom. 5-1/2 in. thick polystyrene foamed plastic core faced on both surfaces with min. 7/16 in. thick oriented strand board. Building Units* loaded to a max of 1800 lb. per linear foot which is 60 percent of recommended axial design load. Porter Corp – Type A Porter Structural Insulated Panels. 2. Studs and Bearing Plates – Nom. 2 by 6 in. thick No. 2 lumber installed in Building Units* (Item 1) in pre-cut channels. End stud and bearing plate secured to the end of oriented strand board with 1-5/8 in. long ring shank nails spaced 12 in. O.C. along the edges on both faces. 3. Gypsum Board* – 5/8 in. thick, 4 ft. wide, applied vertically installed with 1-5/8 in. long high/low bugle-head steel screws spaced 8 in. OC along the edges and 12 in. OC in the field. Vertical joints over vertical joints of Building Units* (Item 1). Gypsum Board joints covered with joint tape and joint compound. Screw heads covered with joint compound. CANADIAN GYPSUM COMPANY – Type C. |

|

| * Bearing the UL Classification Mark | |

See Section 2603 of the IBC “Foam Plastic Insulation” for more detailed information.