The PorterSIPs Advantage

PorterSIPs are the key to energy efficient building. A few reasons why architects and builders are using PorterSIPs:

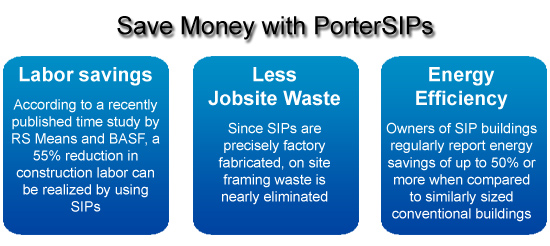

- • SIP buildings use approximately half the energy of conventional buildings.

- • SIPs can be used for virtually any building design and are particularly useful when open designs with long roof spans are desired.

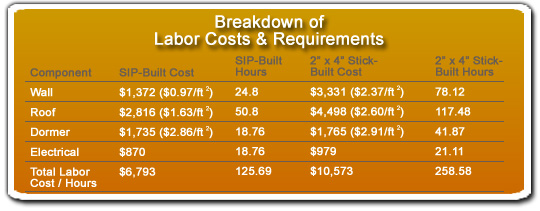

- • SIPs can be erected in approximately half the time of a conventional building.

- • SIPs are an engineered product that can be designed to meet the required loads but are also inherently much stronger that conventional framing.

- • Owners of SIP buildings report less interior noise, fewer drafts, and more consistent interior temperatures due to the continuous foam core inside every SIP.

- • Due to their inherent air-tightness, SIPs make control of indoor air quality possible since incoming air can be filtered and stale air can be expelled in a controlled manner.

- • SIP buildings can be insured less expensively specifically in high wind areas due to their superior strength.

- • Building with SIPs helps earn many LEED points.

Superior Quality

PorterSIPs are designed on state-of-the-art 3D CAD software, are CNC cut, and are audited by a full time Quality Assurance staff. Also, SIPs, due to their balanced composition of OSB on the interior and exterior, are much less likely to bend, bow or twist compared to conventional stick framing. The OSB skins of the panel are continuous and are an engineered product, therefore not as susceptible to “settling” that is common with stick framing. Finally, the PorterSIPs production facility and process is audited for quality by a certified third party inspection agency.

Precision Factory Built

Factory built building components like SIPs are manufactured in an environmentally controlled facility. Compared to field framing, manufacturing in a factory is much more precise with better tools, tighter tolerances, and full time quality inspectors. All of this leads to easier and faster assembly of these components in the field and a higher quality building with fewer problems over its lifetime.

SIPs are the way of the future

SIP technology transcends the building market. It does not belong exclusively to the big or small builders. It does not belong to any one shape, size or style of building. SIPs are a product that is adaptable to customized mass production. No longer must a mass builder confine construction to their repetitive structures in huge plots. Jumbo SIPs can be cut and shaped to various configurations which conform to plans drawn on a computer. With CNC machine-cut SIPs, architects, builders, and owners can easily create custom buildings.