Energy Efficient Building Envelopes

SIPs help to minimize environmental impact

SIPs use their plastic foam core as structure as well as insulation. PorterSIPs use one pound density expanded polystyrene (EPS) foam plastic as the core. EPS foam plastic provides top-performing structure and insulation for this building component.

The insulating core of a structural insulated panel provides continuous insulation. SIPs enable structures to be assembled with minimal in-field framing. The percentage of area in a wall assembly composed of sawn lumber is classified as a wall’s “framing factor.” The framing factor is a measure of thermal bridging. The more framing, the higher the framing factor and the more energy is lost due to thermal bridging. A typical stick-framed home averages a framing factor ranging from 15 to 25 percent, while a SIP home averages a framing factor of only 3 percent. When the whole-wall R-value is measured, SIP walls outperform stick-framed walls where studs placed 16 or 24 inches on center cause thermal bridging and result in energy loss. Additionally, fiberglass and other insulating materials used in stick-framing are subject to gaps, voids, or compression, causing further degradation in thermal performance and drafts.

Building with jumbo SIPs results in fewer joints and is an easy way to build a very air-tight structure. Studies at the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) have shown a SIP room to have 90 percent less air leakage than its stick-framed counterpart. Follow this link to see the full report.

Air leakage in homes is measured by using a blower door test. Using a specially designed fan to negatively pressurize the structure, Home Energy Rating System (HERS) technicians can measure the amount of air leakage in the home and use this information to size HVAC equipment or apply for an ENERGY STAR qualification. SIP-research homes built by ORNL were measured to have infiltration rates as low as 0.03 natural air changes per hour (ACH). Stick-framed homes of similar size in the same subdivision averaged blower door test results ranging from 0.20 to 0.25. SIP homes have proven to reach these levels of air tightness consistently enough for the EPA to waive the required blower door test for homes with a complete SIP envelope to receive an ENERGY STAR rating.

When combined with other high-performance systems, SIP homes can reduce annual energy use by up to 50 percent or more. SIPs have been instrumental in the creation of many zero-energy buildings that produce as much energy as they consume through solar photovoltaic cells and a high performance SIP building envelope.

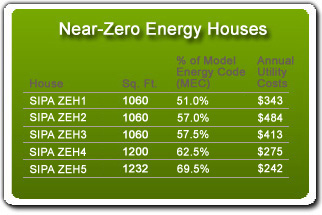

In 2002, ORNL teamed up with the Structural Insulated Panel Association (SIPA) and the DOE to create five innovative net-zero energy buildings. These high-performance homes featured structural insulated panel walls and roofs, roof-top solar photovoltaic systems, and other energy efficient technologies that helped the homes approach DOE’s goal of net-zero energy use.